In the world of high-precision metalworking, there are two processes that seem to cause a lot of confusion: honing and precision ID grinding. Both of these processes are used to improve the form, fit, and function of a metal bore, but they achieve this goal in different ways. In this article, we will explore the differences between honing and precision ID grinding so that you can make an informed decision about which process is right for your parts.

What Is Honing?

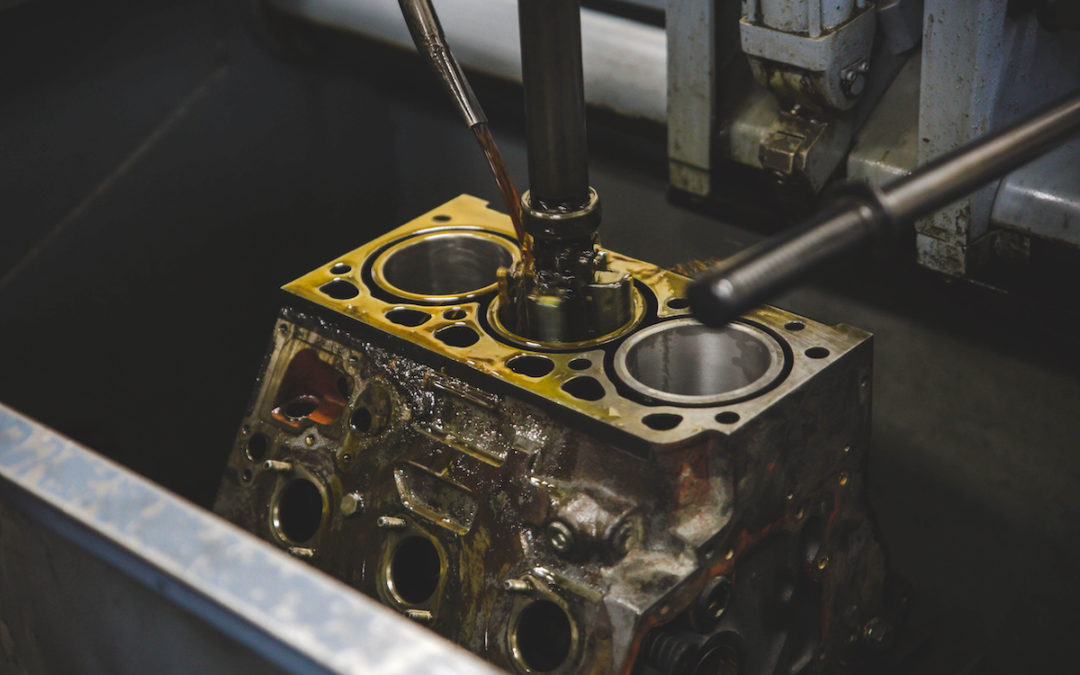

Honing is a finishing process that uses abrasive stones to remove small amounts of material from the surface of a workpiece. Honing is often used to improve the fit of two mating diameters, such as the bore of a cylinder and the piston that goes inside it. The honing process can also be used to create a precise texture on the surface of the workpiece.

ID grinding is a machining process that uses a rotating wheel to remove material from the surface of the workpiece. This process can achieve very tight tolerances, making it ideal for applications where a smooth finish is required.

Honing is a slower process than ID grinding, but it produces a more precise size and finish. This is because honing uses abrasive stones to remove small amounts of material from the surface of the workpiece. The result is a cross-hatched microfinish that is incredibly smooth and consistent. Because of the slow speed at which it operates, honing is typically done by hand rather than by machine.

How Do I Know If I Need Honing or Precision Grinding?

So, which process do you need? The answer depends on a number of factors, including the desired results, the type of metal being worked, timeline, and budget. In general, honing is a more expensive process than precision ID grinding, and it is typically used for high-precision applications where a consistent flow of oil is required. Precision ID grinding is a more cost-effective alternative to honing for lower-tolerance applications where a cross-hatched microfinish is not required.

Typically, honing is the final process in a multi-stage operation to improve the form, fit, and function of the part. The other processes in the sequence will have left their mark on the surface of the part, and these need to be taken into account when considering which process to use for the final finish. However, if a precise cross-hatched finish is not the desired result, a skilled grinder can produce an excellent finish that reduces cost by eliminating the need for additional operations.

Factors to Consider

Surface Finish

The first factor to consider is the desired surface finish. If a cross-hatched microfinish is required, then honing is the best option. However, if a smooth finish is all that is needed, then precision grinding can produce an excellent result.

Material

The type of metal being worked is an important factor to consider when deciding between honing and precision ID grinding. If the metal being worked is soft, such as aluminum, honing may be the better option. If the metal is hard, such as stainless steel, precision ID grinding can provide superior results.

Length to Diameter Ratio

The length to diameter ratio is also something to consider. If the length to diameter ratio is high, honing may be the preferred method. Likewise, if the length to diameter ratio is low ID grinding may be an appropriate application.

Budget

The budget is also an important factor to consider when deciding between these two processes. Honing is typically a more expensive process than precision ID grinding. If cost is a major consideration, precision ID grinding may be the better option. Choosing honing when ID grinding can produce satisfactory results would be a waste of money.

Timeline

The timeline is another important factor to consider. Honing is a slower process than ID grinding, so if time is of the essence, precision ID grinding may be the better option.

Ask Precision Grinding Experts for Advice

The decision between honing and precision ID grinding depends on more than the desired results; your decision should factor in the geometry of the part, the type of metal being worked, the timeline, and the budget. If cost is not a major consideration and a precision microfinish is paramount, honing may be the best option. For most other applications, precision ID grinding can provide excellent results.

Not sure if you need honing or precision grinding? Ask the experts at Duval Precision Grinding today! We can help you determine which process will get the job done right.