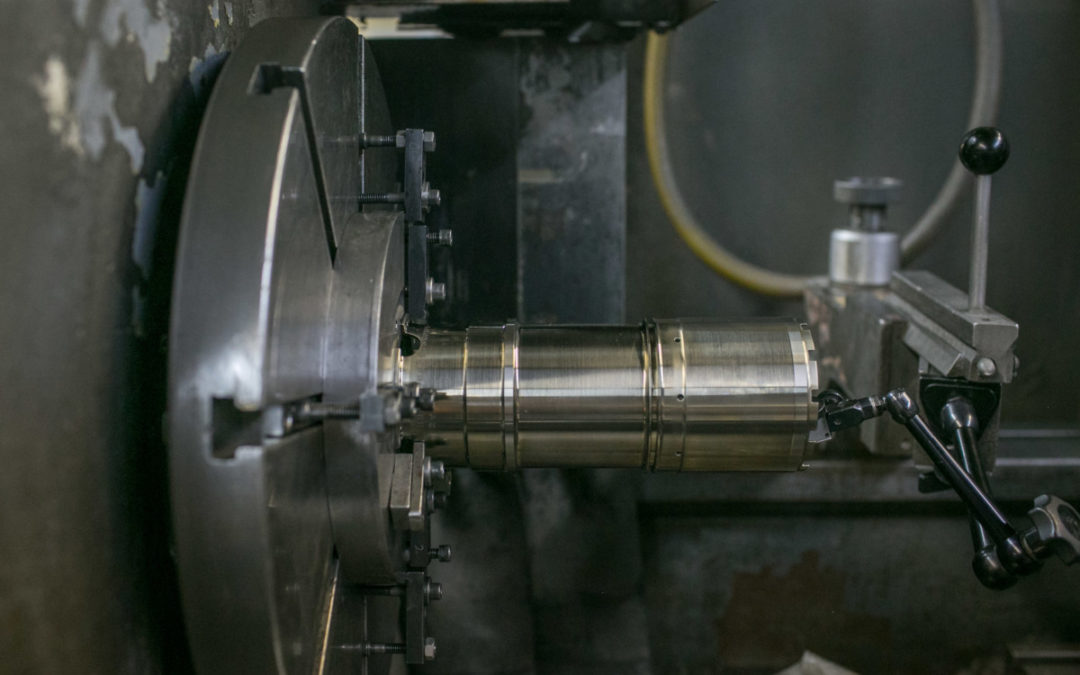

An OEM producing turnkey, automated equipment for the aerospace, renewable energy, biotechnology, and fiber optics industries recently approached Duval Precision Grinding. The customer needed precision grinding on a set of rollers. While many industrial automation equipment components require a lesser degree of precision, the rollers for this client required the same level of precision and attention to detail for which our expert grinders are known.

Meeting the Challenge of Tight Turnaround Times

Initially, the rollers were being shipped from the manufacturer in New England to a grinding house in the Midwest. From there, they were shipped back to a second location in New England to undergo a chemical surface treatment before returning to the customer. This supply chain was long, inefficient, and expensive. The client was keen to find a local grinding vendor who could match the level of precision they required and help them expedite their production timeline. Duval Precision Grinding was up to the task.

Duval’s Expert Process-Engineering Department Streamlines Operations

The customer had an ambitious delivery deadline in mind and the parts were already delayed in transit. With turnaround times tightening, the priority was to set up the new grinding process for this new client as efficiently as possible. We utilized our new process-development strategy to streamline the integration of the client’s product into our workflow.

The demanding nature of the job meant there was a lot of work up front for our process engineers. Through several collaborative sessions and continuous updates, our process engineers and other members of our team worked with the customer’s engineers to achieve an exact understanding of the desired outcomes and specifications. Utilizing the client’s drawings, our expert grinders were able to determine realistic grinding expectations and decide what parts of the process could be streamlined.

Open Communication and Customer Satisfaction

Thanks to a thorough evaluation, solid planning, and great communication, the job went smoothly. When an unexpected delay occurred on the parts being delivered for grinding, a Duval process engineer worked directly with the customer and production scheduling to shift the schedule and absorb the delay—ultimately helping to get the finished parts delivered a full week before the shipping deadline.

The customer noted that Duval’s transparency and open communication was critical to the successful delivery and they appreciated having regular updates that allowed them to plan production schedules more accurately. Now, their supply chain is more cost-effective and efficient and they have a predictable quarterly production schedule. To find out more about precision grinding for automated equipment, contact the experts at Duval Precision Grinding today.