When we say ‘Precision is our only product’ at Duval, we’re referring to more than grinding operations— as many of our customers have come to know and trust! This was the case for a customer in the military support market that required an ITAR-registered precision grinding vendor, and for whom challenges became apparent only after we began our work on what had appeared to be a fairly standard grinding job.

At first, this appeared to be a relatively simple request for our team of skilled grinders, but upon further investigation it became apparent the solution required more than just grinding. Duval worked with the customer and the vendors throughout their supply chain to overcome obstacles and deliver top-quality precision ground parts that would meet and exceed specifications.

Inspection of Damaged and Rusty Machined Parts

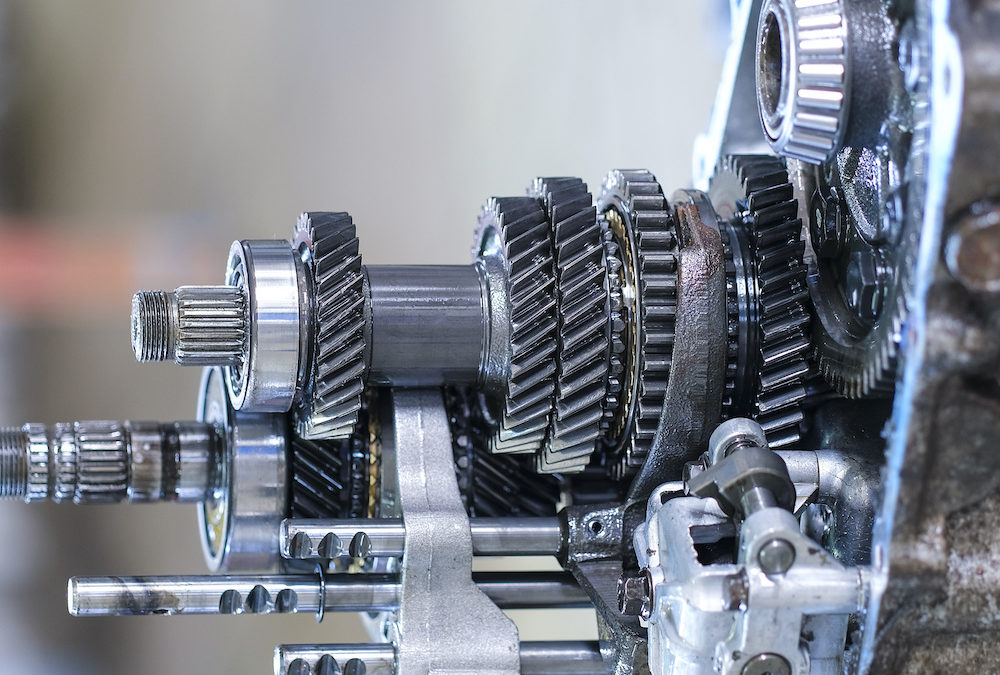

The customer’s requirements specified OD grinding a 32-micro surface finish on 400 steel generator drive gears. The customer decided to outsource machining and fabrication for these parts to a third party machine shop, who was responsible for packing and shipping the parts to Duval for precision finishing. Upon inspection of the raw parts shipped by the customer’s machining partner, poor material handling was identified as a potential issue. A FOD (Foreign Object Damage) investigation was conducted by our Inspection and Shipping departments and concluded that the packaging did not adequately protect the parts, which arrived loose in a large box with no additional padding to absorb the impact the parts incur in transit.

By the time the parts arrived, the damaged areas were already in the early stages of oxidation. The loose parts had turned and collided with each other in transit, creating scratches and dents on the surfaces of the parts. The rust and impact damage would delay production. In some cases, the shipping damage was too severe, making it impossible to achieve the specified dimensions and surface finish.

Supply Chain Collaboration to Improve Packaging

We worked directly with the customer and their machining vendor to develop an improved packaging system that would ensure the safe transportation of the parts. After recommended improvements were implemented and a new shipment of parts was received, Duval performed the planned CNC OD grinding operations, grinding one end diameter and one face, and successfully delivered the parts to the customer. All services were rendered within one month, meeting all deadlines and helping the customer avoid a potential catastrophe without unnecessary delay or expense.

CNC OD Grinding Performed and Parts Delivered On-Time

It’s just one example of how Duval collaborates not only with our customers, but vendors throughout the supply chain, to deliver the best possible end product. After all, everyone involved in the process of production shares responsibility for the safe delivery of parts that meet customer needs, and that’s a responsibility we take seriously. With this in mind, a high-quality end product is a win for everyone involved, as was the case in this situation. Working quickly and efficiently to produce precision parts is just what we do, even if that means extending our consideration beyond the workbench.

Need a precision grinding vendor that will always have your best interest in mind? Contact Duval Precision grinding today to learn how our experts will go the extra mile for you.