Duval Precision Grinding performs complex grinding and surface finishing services for a variety of customers. One of our long-term clients is an OEM that produces complex hydraulic pumps for industrial applications. Unfortunately, the hydraulic pump manufacturer’s source for machining services recently closed without any warning, leaving the customer without a machining vendor. With their current machining service provider no longer in service and their operations at risk of becoming completely halted, the customer turned to Duval Precision Grinding for help.

Leveraging Supply Chain Network to Find a New Machine Shop

Our team of professional grinders was originally contracted as a Tier-2 vendor that would finish the parts and then ship them back to the machine shop before they went to the end customer. When the hydraulic pump manufacturer contacted us about their search for a reputable machine shop, our engineering team met with the OEM to work out the details of their situation.

Over the years, Duval Precision Grinding has established a reliable network of vendors and suppliers. Companies in this network are ones we trust will provide customers the same level of expert precision and reliability we strive to provide every day. After discussing the hydraulic pump manufacturer’s needs, our team was able to put together a quote and establish a new process to get their operations running again. We leveraged our network of vendors and suppliers to find a suitable machine shop and reinitiate production for the hydraulic pump manufacturer.

Precision Grinding Complex Hydraulic Pump Components

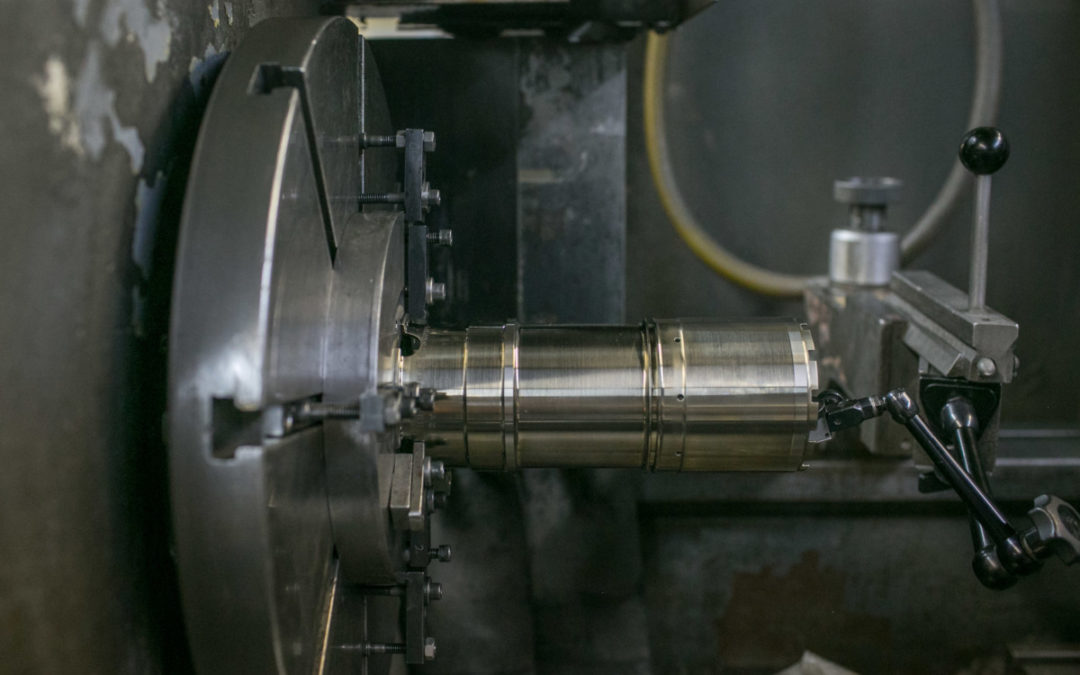

The particular component that Duval Precision Grinding now works on for this customer is made of sintered material—a powdered metal similar to steel that is heated and compressed into a solid piece without being melted into liquid form first. This is a more precise way to cast detailed features on complex parts. Rather than machining every design feature into the metal cast when it is removed from the mold, the piece can be immediately casted with these complex features. Even after these steps, though, some features still require machining and surface finishing performed by professional machining and grinding specialists.

This particular part had some challenging grinding requirements, with very tight tolerances down to +/– .0001”. We test the accuracy of our work by inserting a precision-ground ball bearing that replicates the assembly of the final product. This testing method ensures the correct fit between the two precisely ground parts, but also requires a practiced eye that understands the correct degree of resistance when the parts are fitted together.

Quality Precision and Service from the Grinding Experts

At Duval Precision Grinding, we invest in the success of each of our clients. This is why we are willing to go the extra mile to ensure our customers have access to the right resources and the right service providers. Our team of expert precision grinders will see that your components are finished flawlessly; we will also leverage our network of suppliers and vendors to keep your production schedule running smoothly.

For high-quality precision, contact the grinding experts at Duval Precision Grinding.