Articles & Resources from Duval Precision Grinding

More Efficient Surface Finishing for Hard Chrome Plated Titanium Helicopter Components

Clear communication is a vital part of ensuring the grinding experts at Duval Precision Grinding are able to provide customers the highest level of precision. In a recent collaboration, our experts had been working as a Tier-2 vendor for an OEM who was working closely...

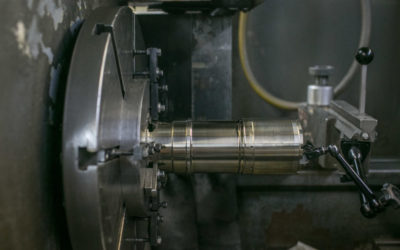

Duval Precision Grinding Helps a Hydraulic Pump Manufacturer Maintain Production

Duval Precision Grinding performs complex grinding and surface finishing services for a variety of customers. One of our long-term clients is an OEM that produces complex hydraulic pumps for industrial applications. Unfortunately, the hydraulic pump manufacturer’s...

Indexed Multistage Precision Grinding Services for Complex, Chrome-Plated Aerospace Components

A producer of parts and subassemblies—for military aircraft, civilian aircraft, and the oil extraction and power generation industries—contacted Duval for the precision grinding of complex aerospace components. This customer regularly supplies individual components...

Precision Grinding of Aerospace Component Samples for Fatigue and Stress Testing

Duval Precision Grinding has a long company history with grinding aerospace components. One of our specialties is radial and surface finishing of coated component samples which are later subject to tensile and fatigue testing by our customers. Aerospace Components...

Prepping for Continued Growth in Precision Grinding for 2017

This has been a record year of growth for Duval Precision Grinding and we are preparing to ramp up for an even bigger year ahead. As January approaches, our team is doing its part to meet with clients; upgrade and maintain equipment; and plan new, landmark goals that...

Interview with an Engineer: Brandon Habin of Alden Discusses the Importance of Precision

Recently, we sat down with Brandon Habin, an engineer with Alden, to discuss the importance of precision in manufacturing. What do you do at Alden? I work with a department that builds, tests, and optimizes systems primarily dealing with water, such as water for power...

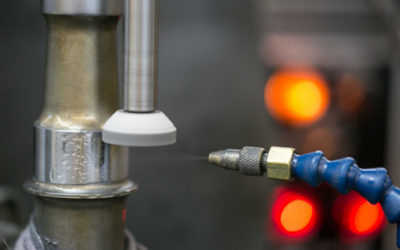

OD Grinding for Plasma-Coated Knife-Edge Engine Seal

Recently, a tier-one manufacturer—known for its ability to handle complex components and assemblies for engine applications in the aerospace industry—approached Duval for the precision grinding services of engine seals. The seals were complex knife-edge seals made of...

Plating Problems: Strong Vendor Relationships Solve Chrome Plating Problem

A longtime Duval customer recently sought our help in solving a difficult supply chain issue that was causing unnecessary delays in their product turnaround time. The customer produces critical aerospace components, for which Duval provides precision grinding...

Flexible Precision Grinding Services Support Increased Customer Demand

Recently, a producer of electronic actuators stopped by our grinding facility to review operations. The OEM has been a Duval customer for nearly a year and the workload has been steadily increasing as their company continues to expand. The customer’s company is...

Building the Team: Duval Precision Grinding Welcomes New Sales and Process Engineer

Our team of grinding and manufacturing experts continues to grow as Duval Precision Grinding forges ahead into the second half of 2016. We’ve added personnel to help accommodate the increased demand for our reliable, high-quality precision grinding services. Customer...

How to Choose A Precision Grinding Vendor