Articles & Resources from Duval Precision Grinding

The Machine-Hours Tango: Planning Pays Off For Duval Precision Grinding

In business, it’s always important to plan ahead. When Duval Precision Grinding recently faced a dilemma involving a sudden surge in demand from one customer and an unexpected lull from another, even their experienced team was taken by surprise. In order to keep up...

Achieving Precision for Naval Components: DPG Delivers High-Quality Results on High Carbon Steel Grinding

Duval Precision Grinding (DPG) recently worked with a customer on a challenging inner bearing ring for a naval application. Duval Precision Grinding is registered ITAR compliant, with an AS9100D and ISO 9001:2015 certified Quality Management System, and offers an...

10 Questions To Ask Your Precision Grinding Vendor

There are many factors to consider when selecting a grinding vendor, and asking the right questions is essential if you’re going to find the best partner for your business. In this article, we will outline 10 important questions to ask potential vendors, as well as...

5 Ways To Reduce Manufacturing Costs With Precision Grinding

Domestic manufacturing is on the rise, and with economic uncertainty looming it is more important than ever to find ways to reduce manufacturing costs while still producing high-quality products. This feat requires optimization throughout the entire manufacturing...

Grinding Corrosion-Resistant Bolts for Aerospace Applications

Duval Precision Grinding has a lot of experience with grinding chrome-plated aerospace components. This experience came in handy recently when they completed a project involving grinding 100 chrome-plated bolts for a company that provides plating and coating services...

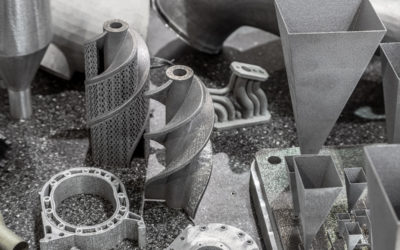

Finish Grinding 3D Printed Metal Components: What You Need to Know

Additive manufacturing (AM) has been steadily gaining traction as a viable option for producing metal parts. While previously limited to prototype development due to high cost per piece, additive manufacturing techniques have worked their way up to the production...

What Is The Difference Between Honing And ID Grinding?

In the world of high-precision metalworking, there are two processes that seem to cause a lot of confusion: honing and precision ID grinding. Both of these processes are used to improve the form, fit, and function of a metal bore, but they achieve this goal in...

Jig Grinding To Restore A High-Value Spindle Housing

When it comes to precision grinding, Duval is your go-to source. Recently, we completed jig grinding work for a customer who needed to repair a cutter spindle housing for some high-value manufacturing equipment. The cutter spindle housing is an important part of a...

Grinding Stellite Spherical Bearing Sleeves for Military Applications

Duval Precision Grinding was recently contracted to finish a Stellite sleeve for a spherical bearing assembly used in a naval application. Stellite is known for toughness— abrasion, corrosion, and wear resistance in particular. Due to the hardness of Stellite, it is...

Reconsidering ESI: Can Early Supplier Involvement Help Combat Long Lead Times?

Manufacturing lead times have been increasing for several reasons, including the rise in global demand, transportation meltdowns, and the tightening of the labor market. While some businesses have been able to mitigate the effects of these delays with supplier buffers...

How to Choose A Precision Grinding Vendor