At Duval, our company motto is: Precision is our only product. It is more than just a saying—to us, it is a commitment. Many of the OEMs who approach Duval Precision Grinding produce equipment for industries like aerospace and power generation, where quality regulations are particularly strict. We produce each part to specification and maintain the level of quality our customers expect by utilizing a rigorous quality-inspection process.

High-Quality Precision Grinding Services

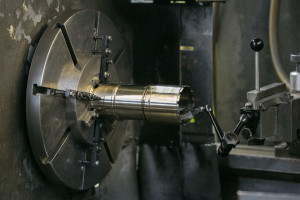

Our expert precision grinding staff is able to grind and finish virtually any equipment component with tolerances up to +/–0.0001”. When dealing with measurements so small, maintaining accuracy can be exceedingly difficult. Thermal expansion, component materials, and specialized coatings can all have an effect on the final measurements. Duval’s multistage quality inspection process takes these factors into account, ensuring that the tolerances for each component have been measured precisely. This includes rechecking measurements and regrinding each part after any coating or plating processes. Experienced machinists and operators make sure that the final product, including its plating or coating thickness, meet our customers’ precise specifications.

Our expert precision grinding staff is able to grind and finish virtually any equipment component with tolerances up to +/–0.0001”. When dealing with measurements so small, maintaining accuracy can be exceedingly difficult. Thermal expansion, component materials, and specialized coatings can all have an effect on the final measurements. Duval’s multistage quality inspection process takes these factors into account, ensuring that the tolerances for each component have been measured precisely. This includes rechecking measurements and regrinding each part after any coating or plating processes. Experienced machinists and operators make sure that the final product, including its plating or coating thickness, meet our customers’ precise specifications.

Precision Grinding Inspection Equipment Capabilities

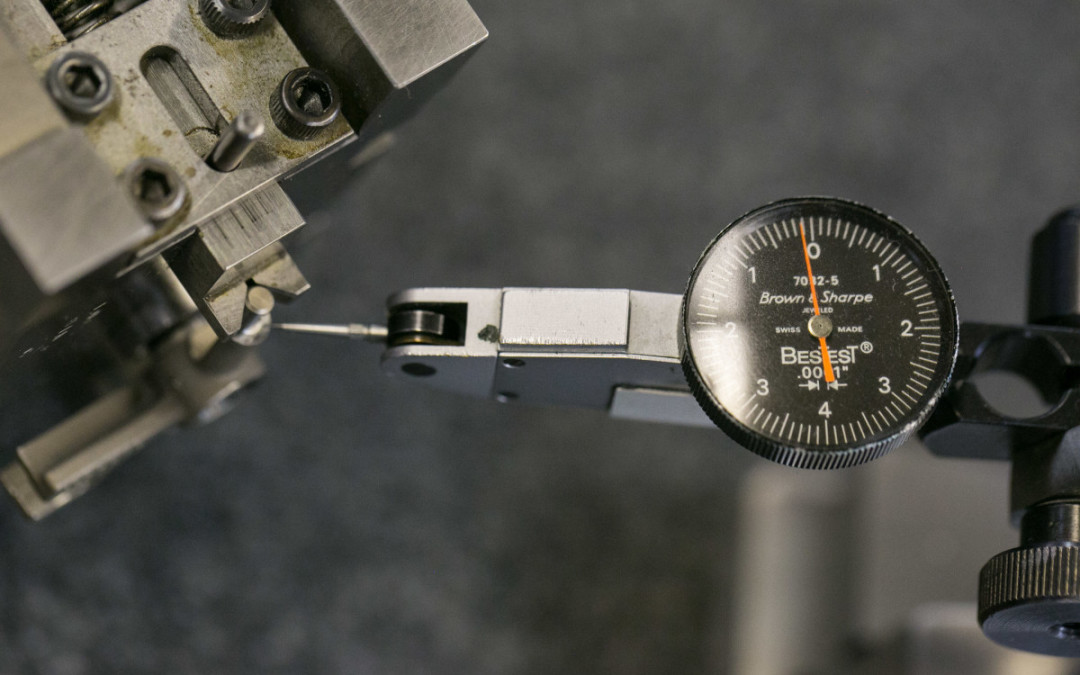

Tight tolerances require methodical inspection to guarantee accuracy. Those tolerances can sometimes be loosened to permit quicker production. However, if the dimensional requirements for the part are strict, Duval is fully equipped and qualified to precisely measure extremely tight tolerances. Our inspection equipment is as follows:

Standard Gauge Blocks: These are used as a reference source to verify the accuracy of other measurement equipment.

Standard Gauge Blocks: These are used as a reference source to verify the accuracy of other measurement equipment.

Micrometers: Micrometers are simple but highly accurate measurement tools that can read to 0.0001”.

Profile Projector: Our new Mitutoyo shadowgraph enables very precise measurement of forms, angles, radii, and more. Light-sensing technology allows this machine to produce highly accurate readouts detailing various geometries for complex, precise components; it virtually eliminates the risk of user error.

CMM Scanning Probe and CMM Traditional Probe: CMM inspection allows Duval’s skilled operators to perform complicated measurements that would be impossible with conventional equipment. The scanning probe scans diameters without being restricted by the physical limitations of the touch probe. Our CMM inspection services can also digitally compare real-world measurements to CAD models to precisely match design specs.

Ensuring Accuracy with a Rigorous, Multistage Inspection Process

When we receive an order for a new part, our engineering and operations manager, quality manager, and precision grinders meet to review the component design and ensure they understand the requirements that must be met to successfully complete the job. They determine the best way to measure the part based on its material composition, the sequence of required grinding operations, and the part geometry.

Once grinding begins, the part is put through a series of quality-assurance checks for each grinding stage. Before inspection, the part is placed in a climate-controlled inspection room to minimize the effects of thermal expansion. The part is then measured by highly qualified CMM-inspection programmers and operators; this inspection team has over thirty years of experience in the aerospace and precision grinding industries. These highly trained professionals use two forms of measurement for every part to eliminate the risk of human error and guarantee accurate results.

At Duval Precision Grinding, we’re committed to delivering the highest-quality results for every part. By measuring each part in a multistage process and by using multiple measurement tools, we are able to guarantee that each part meets its design specifications. If you have a difficult component with challenging precision requirements, contact the experts today.