Since 2023, Duval Precision Grinding has provided precision grinding services to an Iowa-based manufacturer specializing in fuel nozzles and fuel delivery components. This aerospace-focused customer turned to Duval for precision grinding expertise in high-temperature, high-performance applications. What began as a single project has grown into an ongoing program, with several orders completed to date that have helped to establish a more stable supply chain for this aerospace manufacturer.

High-Precision Grinding for High-Temperature Fuel Cell Components

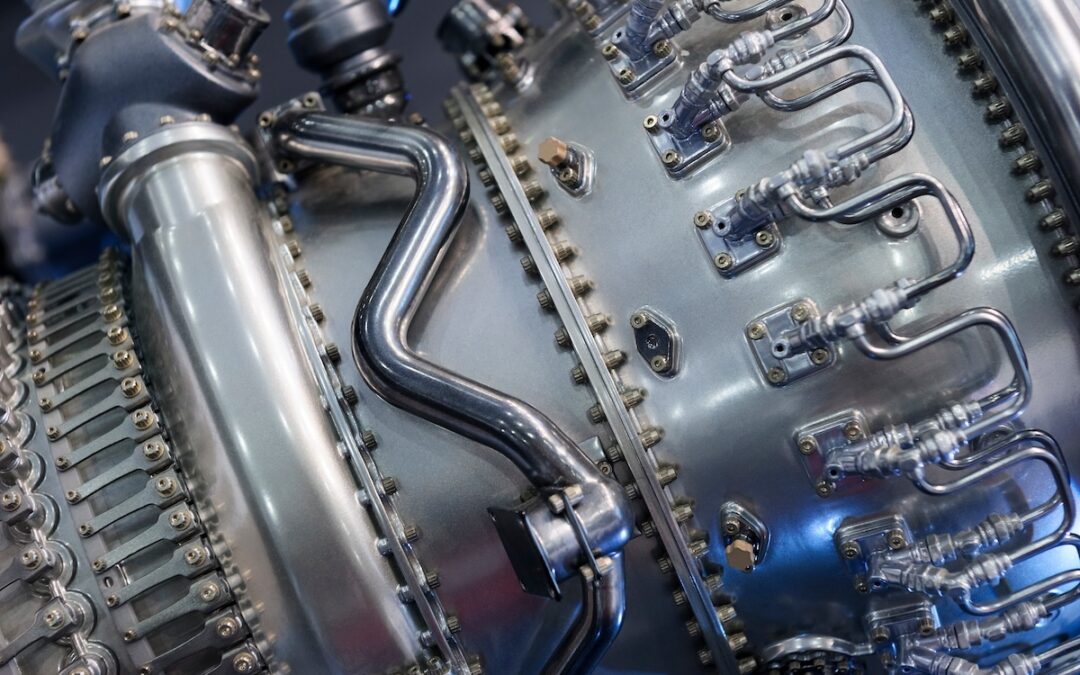

The project involved grinding critical components for fuel cells operating in high-temperature environments. These components featured a cobalt-based coating known for its superior wear resistance and durability in extreme conditions. Grinding operations included:

- Surface grinding to remove excess HVOF material.

- OD grinding to achieve precise dimensional accuracy.

- A final surface grind operation to 32-micro finish.

This project posed unique challenges due to tight tolerances, quick turnaround times, and the need for seamless coordination between the client, plater, and Duval Precision Grinding. Accuracy and collaboration were key to ensuring the components met aerospace’s demanding regulatory standards.

Surface and OD Grinding of HVOF-Coated Aerospace Parts

Drawing on decades of experience with aerospace components, Duval Precision Grinding developed a process tailored to the client’s needs. After signing a Non-Disclosure Agreement (NDA) to handle sensitive information, Duval’s team worked closely with the customer to refine the grinding approach.

A customer-provided fixture ensured accurate dimension qualification and repeatability, enabling Duval’s grinders to consistently maintain ±0.0001-inch tolerances. A 32-micro finish was reached through precise control of grinding speeds, feeds, and abrasives, ensuring both the dimensional integrity and surface quality of the HVOF-coated components.

By optimizing workflows and integrating advanced CNC grinding equipment, Duval Precision Grinding reduced setup times and enhanced efficiency. These improvements allowed for an average production time of 54.5 hours per order, even with varying lot sizes.

Each shipment included a Certificate of Conformance (C of C) and Inspection Report, providing the client with full assurance of quality and compliance. By meeting tight deadlines and delivering parts that perform reliably in high-temperature environments, Duval Precision Grinding has become a trusted partner for the client’s ongoing fuel cell production program.

Supporting Aerospace Manufacturing with Precision Grinding

By combining technical expertise with collaborative customer relationships, Duval Precision Grinding ensures that every component meets the exacting standards required for mission-critical applications. Our team works closely with clients to understand their unique requirements, offering tailored solutions that prioritize precision, consistency, and reliability. From optimizing grinding processes to maintaining open communication at every step, we are committed to delivering parts that not only meet specifications but also perform flawlessly in the field. With decades of experience and state-of-the-art equipment, Duval Precision Grinding is a trusted partner for industries where quality is non-negotiable.

Smooth Finishes, Superior Results

Duval Precision Grinding delivers the surface finish quality your project demands with precision and consistency. Our expertise ensures every component meets exacting standards, ready to perform in the most critical applications.