Since its founding, Duval Precision Grinding has cultivated a reputation for approaching every job with a level of care, commitment, and attention-to-detail that is second to none in the industry. These qualities were on display once again recently, when a new client reached out to the team at DPG regarding some very precise jig grinding needs.

This organization had already been hard at work machining a number of parts for an OEM in the aerospace sector. They needed specific and very precisely measured holes inserted into paired left and right matching aluminum brackets, all through precision jig grinding. However, they now found themselves with a challenge due to their own limited in-house grinding capabilities, which could not achieve the required tolerances.

Any deviation from the print would result in mismatched bracket pairs, rendering the components unusable. By turning this job over to the expert precision grinders at DPG work was able to continue without delay, saving valuable time.

ITAR Registered & AS9100 Certified Precision Jig Grinding

The customer began by providing a technical drawing of the required brackets, which gave the team at Duval all the actionable information they needed to perform the jig grinding operations needed to bring the part to spec. Working on this job required not only ISO 9001 and AS9100 certification, but ITAR registration as well due to the nature of the client and the end application of the components.

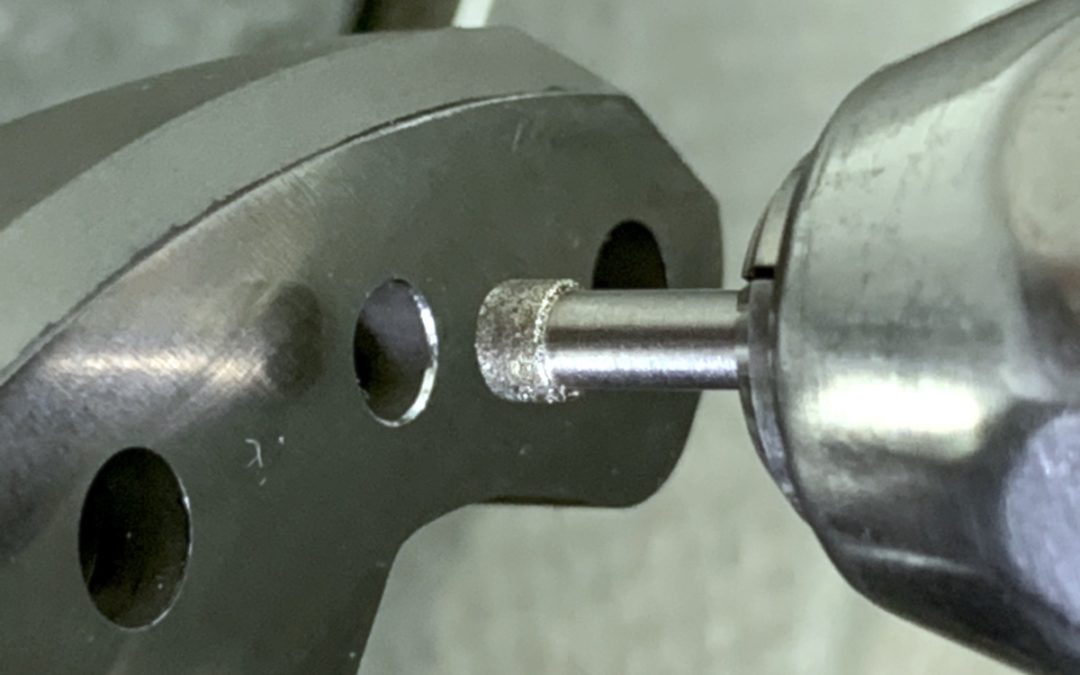

DPG was working with two mirrored versions of the part: a “left” and “right” version. The aluminum brackets would be finished with conversion coating. This required precision jig grinding in two diameters – one at roughly Ø.500”, with the other at roughly Ø.400. Keep in mind that both needed to be within ±.0001” – absolutely no exceptions.

Because of the tighter tolerances, temperature can quickly become a concern due to the high coefficient of thermal expansion for aluminum materials. Carefully managing the temperature of the component throughout the grinding process is critical to ensure repeatable and accurate results— achieved in part through the application of different grinding techniques and tools, as well as maintaining our facility at 68 degrees Fahrenheit year-round.

Duval Precision Grinding Will Exceed Your Expectations

In the end, Duval Precision Grinding was chosen because we have years of experience and a reputation for completing the types of jobs that others can’t. Despite the challenging circumstances, this was fairly typical for the team at DPG. Duval actually performs numerous grinding operations for machine shops that either don’t have the grinding capabilities to do them on their own, or who are limited in what they can do, saving valuable time and labor for customers.

When it comes to grinding, our hardworking precision grinding professionals have the tools, the talent, and the experience needed to meet your needs and exceed your expectations. If you have any additional questions about our jig grinding capabilities, or if you just want to discuss your own needs with someone in more detail, contact Duval Precision Grinding today.