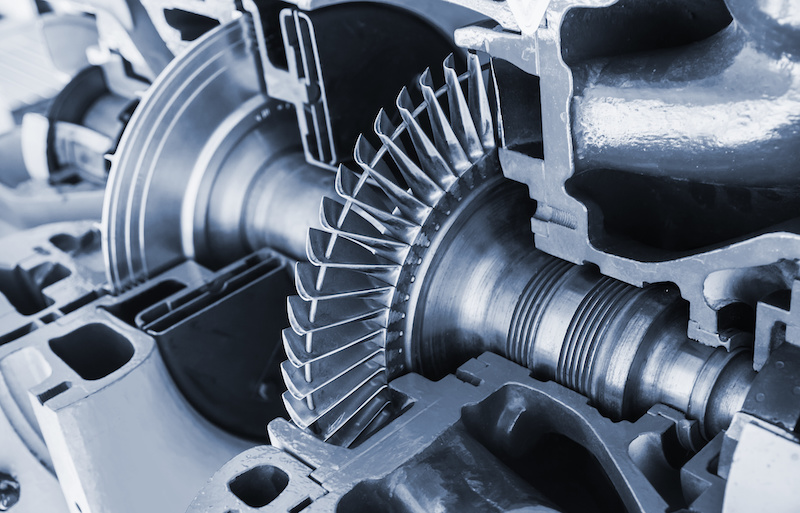

Duval Precision Grinding is highly adept at performing the kind of complex grinding operations that are required for producing many different types of flight-critical components in the aerospace industry. Recently, we completed a large job producing a compressor rotor assembly for a turbine engine designed for military planes.

Specialty ID Grinding and OD Grinding Multistage Process

The customer was a specialty machine shop that required precision grinding on a compressor rotor assembly that needed to be completed in two separate stages. The part would initially be sent to Duval for a series of surface grinding and OD grinding operations that would condition the part for the next stage of production. The part was then returned to the customer, who would then assemble the turbine engine bushings into the part. Once assembled, the part was returned to our team for rotary surface grinding and a specialty ID grinding operation to finish the surface of the part.

The customer was a specialty machine shop that required precision grinding on a compressor rotor assembly that needed to be completed in two separate stages. The part would initially be sent to Duval for a series of surface grinding and OD grinding operations that would condition the part for the next stage of production. The part was then returned to the customer, who would then assemble the turbine engine bushings into the part. Once assembled, the part was returned to our team for rotary surface grinding and a specialty ID grinding operation to finish the surface of the part.

Custom Tooling & Fixturing Ensures Accuracy for Flight Critical Components

The part, made of aircraft quality low alloy steel, did not require any coatings or surface treatments however, the specifications for completing the part included multiple tolerance requirements up to 0.0005”. To ensure accuracy during grinding, our grinders developed and produced custom ID and OD locating fixtures. Creating custom tooling and fixturing to guarantee accuracy on complex parts is one of our specialties, and our team was able to complete the work for the customer without any issues.

For more information about precision grinding services for aerospace components, contact the experts at Duval Precision Grinding, today.